Diagnosing a Toyota PO420 Code

Diagnosing a Toyota PO420 Code

A couple of weeks ago a 2002 Toyota Corolla came into the shop with the P0420 code. If you have been working on cars for any period of time, I’m sure your familiar with the P0420 Catalytic Converter Efficiency Below Threshold code.

This seems like it should be a very straight forward code. Most tech’s will skip the diagnostic process all together, and just throw a catalytic converter in it. This is an extremely expensive guess!

The first step I always take is to confirm that the catalytic converter is actually bad. You can usually accomplish this on a quick test drive while monitoring some live data on your scanner.

Setting Up Your Scanner

You will want to graph the data, if your scanner does not graph, you are better off using a lab scope.

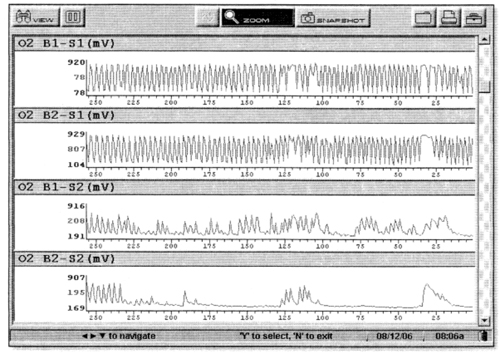

Cat Converter Graphed DataFirst, choose just the sensors you want to look at. In my case, I was working on a 4 cylinder, so I just had bank 1 upstream and downstream to look at. The picture to the right illustrates a two ban system.

For a proper test you will want to monitor the data at many different RPM ranges. The most important range to look at, is at a steady 2,500 RPM. The rule of thumb is no more than 1 cross count on the downstream O2 Sensor for every 7 cross counts on the upstream O2 Sensor. If the downstream O2 Sensor is mirroring the upstream, the catalytic converter is definitely bad.

Back To the Toyota At Hand

On my test drive, I got very erratic results. At some RPM ranges the downstream O2 sensor was going crazy and at others the Catalytic Converter appeared to be working properly. I decided to look at some more data.

The first thing I wanted to look at was the Short and Long Term Fuel Trim. The long term was at -7 and my short term was maxed out at -25, showing a rich running condition. My first thought was a bad coolant temperature sensor. After looking at the data I ruled it out. I then focused on the Mass Air Flow Sensor, everything looked good there. I went for another test drive while monitoring the fuel trims, I noticed at certain RPM ranges the fuel trims were trying to to correct themselves, indicating a air flow problem.

the Mass Air Flow Sensor, everything looked good there. I went for another test drive while monitoring the fuel trims, I noticed at certain RPM ranges the fuel trims were trying to to correct themselves, indicating a air flow problem.

When I got back to the shop I noticed that the idle was a little higher than it should be while in park. I loaded the system by putting the car in drive, turning on the A/C and high beams. The idle dropped down to about 550 RPM’s. I then went to the activations menu in my scanner and tried to activate the Idle Control Valve (IAC). I got no response from the IAC. I tested the IAC circuit, everything checked out there. The only thing left was the Idle Control Valve.

After replacing the Idle Control Valve, the idle responded correctly, the fuel trims started to correct themselves and most importantly the O2 Sensors showed that the catalytic converter was functioning properly.

Conclusion

So in conclusion, there was nothing wrong with the catalytic converter at all. The Idle Control Valve was stuck in one position, causing an air flow problem. At times the fuel to air ratio was to lean but most the time it was far too rich. The catalytic converter could not keep up with the amount of raw fuel going through it. A rich running condition will destroy a catalytic converter. Luckily we cought the problem before it caused any serious problems.

When dealing with Catalytic Converter issues it is very important to look at the whole picture. Catalytic Converters usually don’t just go out for no reason and it is very important to not only make sure that it is actually bad. But to also make sure the entire fuel system is functioning properly. Without finding the root of the problem it is just going to keep coming back with the same issue.